HARVEYPOW Inside the LiFePO4 Battery Factory-Powering the Future

Introduction

The future of energy storage is here.

LiFePO4 batteries are revolutionizing the way we power our lives, and their production is already beginning to shape the world around us.

Inside a LiFePO4 battery factory, we get a peek into what the future holds - from how these batteries are made to how they can be used for a variety of different applications.

From electric vehicles to home energy storage, LiFePO4 batteries have become an essential part of modern life.

This article will explore the inner workings of a LiFePO4 battery factory, and explain how these batteries are being used to power the future.

From raw materials to finished products, every LiFePO4 battery goes through a complex process before it is ready for use.

In order to understand just how impactful these batteries are, it's important to look at the manufacturing process in detail.

At the heart of this process is an intricate combination of chemistry and engineering that has been perfected over time.

From selecting components and testing them for quality assurance to assembling individual cells into larger packs, there is much more than meets the eye when it comes to making LiFePO4 batteries.

Finally, understanding exactly how these batteries are made can help us better appreciate their potential in our lives today and in years to come.

As LiFePO4 technology continues its march forward, factories like these will become even more integral in meeting global energy needs and powering our future with sustainable solutions.

By taking a closer look inside a LiFePO4 battery factory, we can see firsthand just how powerful this technology really is!

How Lifepo4 Battery Makes a Great Different in Current Modern World

How Lifepo4 Battery Makes a Great Different in Current Modern World

LiFePO4 batteries are quickly becoming a major player in the world of energy storage.

They offer several advantages over traditional lead-acid and lithium-ion chemistries, including higher energy density, greater cycle life, and better safety performance.

These benefits make LiFePO4 batteries ideal for use in electric vehicles, utility-scale energy storage systems, and many other applications.

The production of LiFePO4 batteries is an intricate process that requires careful attention to detail.

Starting from raw materials such as cobalt oxide or graphite, these components are blended together with a binder and then formed into electrode plates of varying thicknesses.

The plates are then placed into metal containers filled with electrolyte solution and connected to terminals to form the finished battery cell.

The components used in the production of LiFePO4 batteries must meet strict quality standards in order to ensure the battery's performance and safety.

To this end, manufacturers rigorously test each component at each stage of production to ensure its compliance with industry standards. Strict quality control measures also help ensure that only high-quality cells are shipped out of the factory.

As LiFePO4 batteries become more widely used, their importance will continue to grow as they power our future.

With the world increasingly turning to LiFePO4 batteries for a number of functions, it is important to understand what goes on inside the factory.

This blog will explore how these powerful batteries are made, from start to finish.

First, we'll look at the raw materials that make up the battery cells.

This includes lithium cobalt oxide cathode material, graphite anode material, electrolyte solution and separators.

These are all sourced from global suppliers and brought into the factory in bulk.

At this point, these components are combined and put through a series of tests that check their performance, quality and safety standards.

Once they pass these tests, the battery cells can be assembled into packs and modules ready for use in various applications.

It is only then that these LiFePO4 batteries can be shipped off to customers around the world and used to power many aspects of our lives.

Lifepo4 Batteries Have Excellent Performance over Other Types of Batteries

LiFePO4 batteries are a type of rechargeable lithium-ion battery.

They are made up of a combination of lithium and iron phosphate, which is why they are also known as LiFePO4 cells or LiFe batteries.

These batteries offer numerous advantages over other types of rechargeable batteries, making them increasingly popular in many applications.

The first advantage is the high energy density these batteries possess. This allows them to store more energy than other types of rechargeable batteries, meaning they can be used for longer periods of time before needing to be recharged.

In addition, LiFePO4 cells have extremely low self-discharge rates, meaning that even when not in use for extended periods of time, LiFePO4 cells retain their charge much better than other types of rechargeable batteries.

Furthermore, LiFePO4 batteries are much safer than other forms of lithium-ion batteries due to their low internal resistance and thermal stability when compared with other forms such as Lithium Cobalt Oxide (LCO) or Lithium Manganese Oxide (LMO).

This makes them ideal for applications where safety is paramount such as electric vehicles or medical equipment.

With all these benefits combined, it is no wonder that LiFePO4 batteries are becoming increasingly popular in many industries and applications.

Inside Our LiFePO4 Battery Factory

Inside Our LiFePO4 Battery Factory

●the process of lifepo4 battery production

Moving on from the advantages of LiFePO4 batteries, let's look at the process of making them.

The first step is to mix together the raw materials that make up a LiFePO4 battery.

These raw materials include lithium iron phosphate, carbon and electrolytes. They are mixed in precise proportions to ensure optimal performance of the battery.

Next, electrodes are created using these components.

The electrodes are then attached to a steel case, which provides protection for the cells inside.

Then, various other components such as separators, conductors and terminals are added. This assembly process requires great attention to detail and accuracy in order to produce a reliable product.

At last, the assembled battery is tested for safety and quality assurance before it is ready for use.

Once approved, the battery can be used in a wide range of applications including electric vehicles and energy storage systems.

With this process, LiFePO4 batteries have quickly become one of the most popular types of rechargeable batteries available today - powering the future with clean energy solutions.

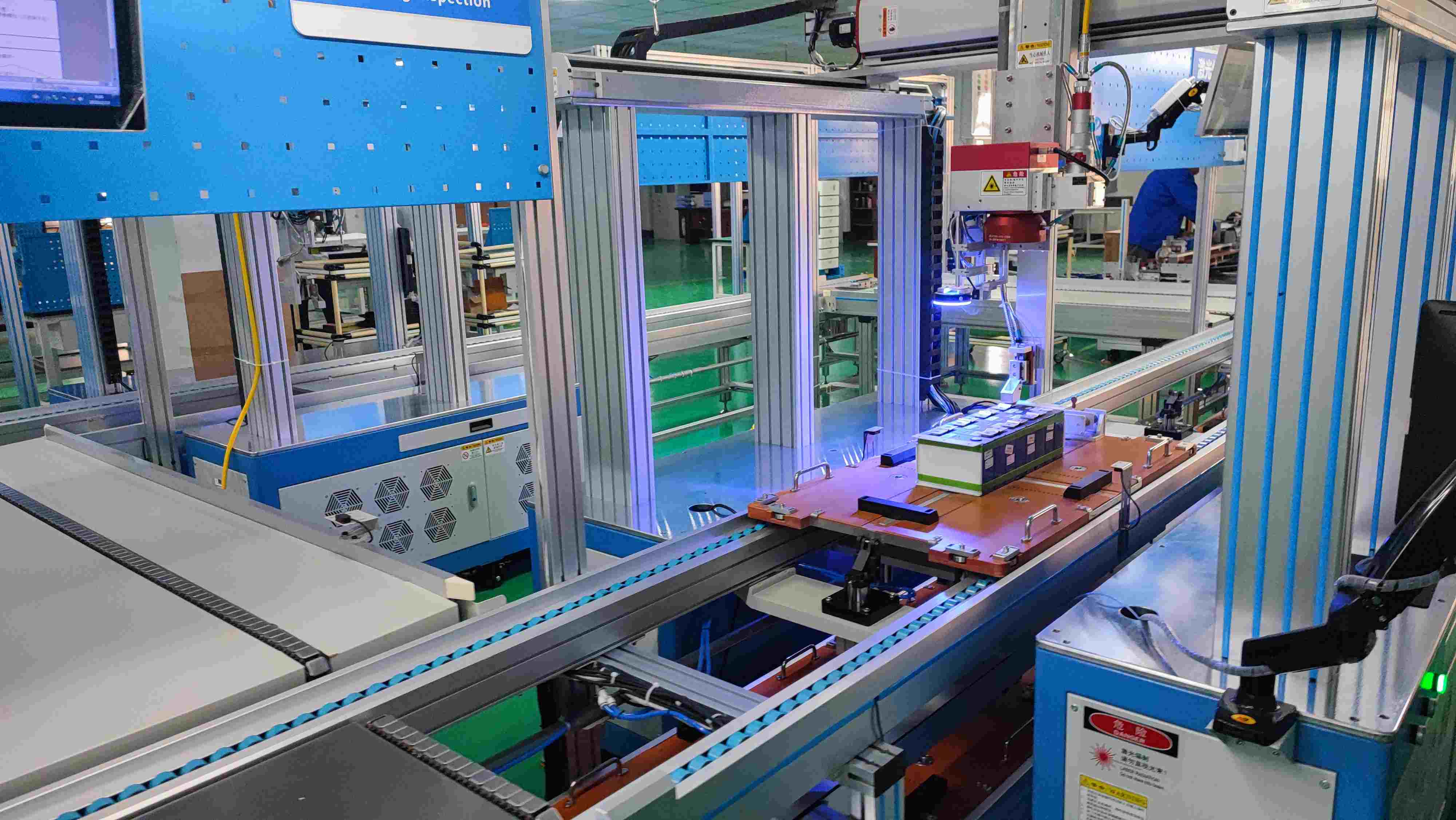

●advanced machines and equipment

The factory is filled with a variety of machines and equipment that are integral to the production process.

The first machine that is used in the factory is a ball mill.

This machine grinds up raw materials into a powder which is then used to form electrodes.

Ball mills are loud and require regular maintenance, but they are essential for producing quality products.

Secondly, hydraulic presses are used to shape the electrodes into the desired shapes.

These presses use high pressure to create precise shapes and sizes, which improves product consistency.

Finally, winding machines are employed to wrap metal foil around the electrodes, creating a protective layer for them. The precision required by these machines makes them an invaluable part of the production process.

Overall, these machines and equipment play an important role in creating high-quality batteries.

They help ensure that each battery is safe and reliable, thereby allowing companies to power their future with confidence.

● quality control measures taken during the manufacturing process to ensure the batteries meet safety and performance standards

The quality control measures taken during the manufacturing process of a Lifepo4 battery are rigorous and comprehensive.

They start with material selection and end with performance testing.

First, materials used in battery production are stringently checked for quality and consistency.

All components must meet strict requirements before being approved for use.

In addition, modern computer-controlled machines are employed to ensure that all components are machined accurately and precisely.

The assembly process is also highly regulated.

Each stage is carefully monitored by experienced technicians who ensure that all parts fit correctly, the assembly process is followed correctly, and that no steps have been missed or overlooked.

Moreover, inspection stations are set up at various points in the assembly line to check each battery's integrity, including its terminals and connections.

Any batteries not meeting standards are immediately identified and removed from the production line.

Therefore, when the battery has been fully assembled, it undergoes a series of performance tests to determine if it meets safety and performance standards set forth by industry guidelines.

These tests can include charge/discharge cycles, temperature cycling tests as well as electrical safety tests among others.

After passing all these tests successfully, only then will the battery be ready to be released from the factory for sale to customers around the world.

The Challenges Faced By Lifepo4 Battery Manufacturers

The Challenges Faced By Lifepo4 Battery Manufacturers

The manufacturing of LiFePO4 batteries comes with many challenges.

One of the toughest is sourcing raw materials. As these batteries are composed of several different components, such as electrodes, electrolytes, and separators, manufacturers must find reliable sources for each material.

This can be difficult and time-consuming, especially when dealing with rare or scarce materials.

Additionally, some materials may be hard to come by depending on where the factory is located.

Another challenge faced by producers of LiFePO4 batteries is improving production efficiency.

Many factories are still using outdated methods like manual assembly lines that are slow and inefficient.

With so much competition in the market today, it's essential for LiFePO4 battery manufacturers to improve their production speed in order to stay competitive.

To do this they must invest in new technology and equipment that can help them speed up the process while still maintaining a high level of quality control standards.

Despite these issues, LiFePO4 battery manufacturers must also consider factors such as cost control and environmental sustainability when producing their products.

As demand for LiFePO4 batteries increases, so does the need for companies to maintain tight control over costs while also ensuring their products are produced in an eco-friendly manner.

This means investing in technologies that limit wastefulness and make use of recycled materials whenever possible.

By doing so, LiFePO4 battery manufacturers can not only remain competitive but also show they care about the environment.

The Recent Innovations In Lifepo4 Battery Technology

In recent years, great strides have been made in LiFePO4 battery technology.

New electrode materials, such as graphite and cobalt oxide, are being used to increase the energy density of LiFePO4 batteries.

These new electrodes allow for higher charge and discharge rates, allowing for more efficient use of the battery over a longer period of time.

Another major development has been the implementation of thin films on the electrodes.

This allows for a better distribution of ions throughout the battery, resulting in improved power output and reduced internal resistance.

The use of these thin films also increases the battery's cycle life by reducing self-discharge rates and maintaining its voltage over multiple cycles.

These innovations have helped make LiFePO4 batteries more efficient than ever before.

They offer a reliable power source for many industries, from consumer electronics to electric vehicles.

With further advancements expected in the near future, LiFePO4 batteries are sure to remain a key part of powering our future.

Harvey Power Is The Advanced Factory that Has The First-Rate Production Line

Harvey Power Is The Advanced Factory that Has The First-Rate Production Line

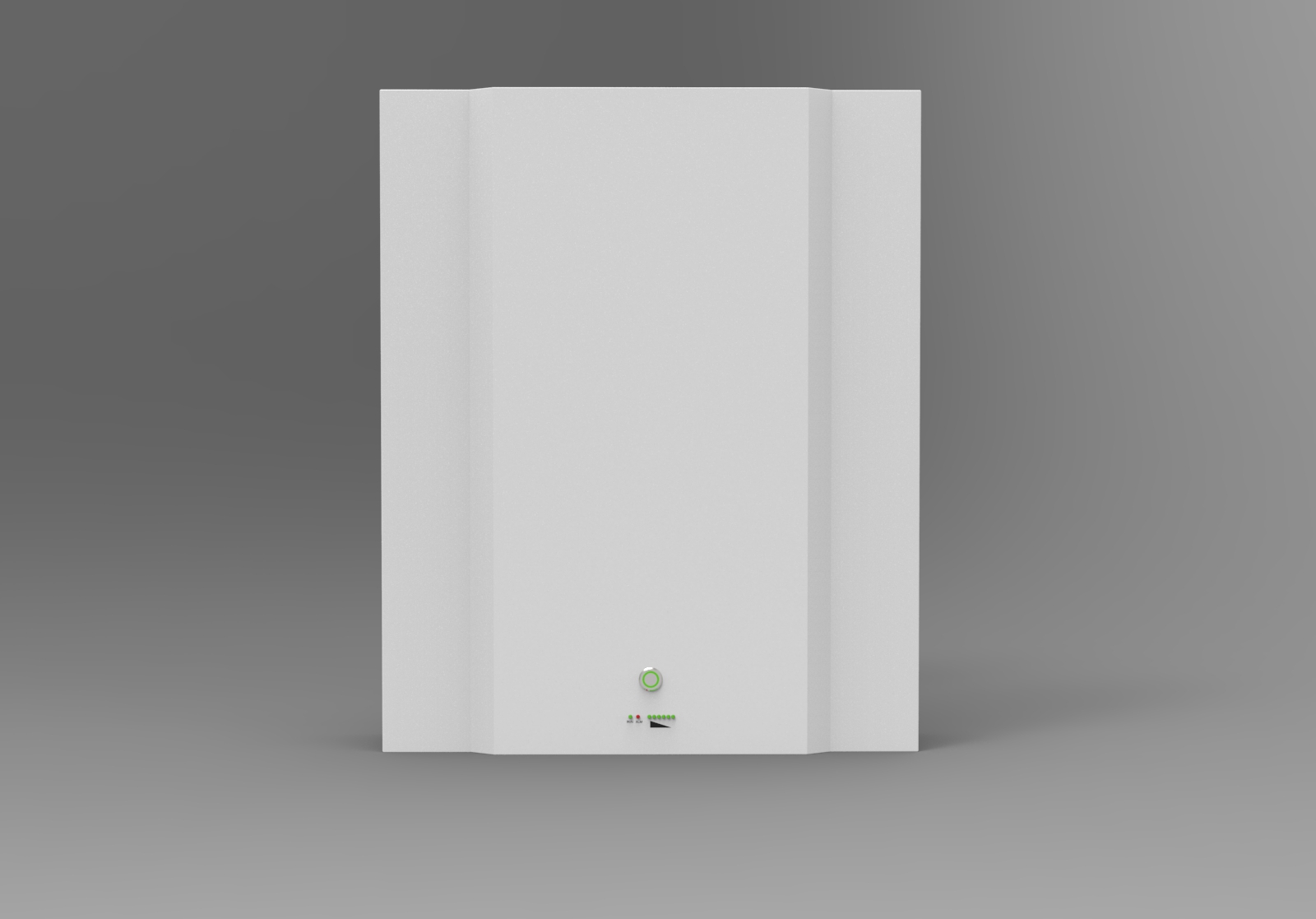

Harvey Power is a state-of-the-art LiFePO4 battery factory with a first-rate production line.

It has recently made some of the most significant advances in the industry, such as its proprietary technology for creating improved electrodes to increase energy density and extend shelf life.

Its research and development efforts have led to an advanced production system that produces high-quality batteries at a low cost.

The factory features a highly automated process with robotic arms, advanced sensors, and specialized equipment that allow for precise monitoring of each individual battery during the manufacturing process.

This ensures quality control throughout the entire production line.

The robotic arms can also be programmed to perform routine maintenance tasks, allowing for less downtime and more efficient production.

Harvey Power's manufacturing processes are streamlined and efficient, leading to faster turnaround times on orders and less waste material.

Its commitment to innovation combined with its focus on quality makes it one of the top LiFePO4 battery manufacturers in the world today.

By continuing to lead the way in cutting-edge technologies, Harvey Power is helping to power the future of sustainable energy solutions.

Conclusion

The importance of LiFePO4 batteries in powering the future cannot be understated.

In today's world, these batteries are essential for modern life, from powering electric vehicles and mobile devices to providing energy storage for renewable energy sources.

As such, it is important to understand the process that goes into making these batteries.

By exploring what happens inside a LiFePO4 battery factory, we can gain a better understanding of how these batteries are made and appreciate the range of machines and processes involved in their production.

We have also seen how technological advances have improved the performance of LiFePO4 batteries, with new electrode materials and higher energy densities leading to more powerful and efficient products.

Harvey Power's advanced factory is at the forefront of this technology, offering first-rate production lines that ensure high-quality LiFePO4 batteries are produced with maximum efficiency.

Thanks to manufacturers like Harvey Power, LiFePO4 batteries will continue to power the future into an even brighter tomorrow.

Leave A Reply

We've looked at the inner workings of a LiFePO4 battery factory and seen how it is powering the future.

Now, let's take this discussion one step further and open up the conversation to our readers.

What do you think about this technology?

How can LiFePO4 batteries be used to benefit society in the near future?

We would love to hear your opinions and ideas on this topic.

Do you have personal use and maintenance experience of LiFePO4 batteries to share?

Are there any challenges or issues that you think should be addressed?

We welcome all perspectives, so please don't hesitate to comment below or reach out with your thoughts.

Your insights could help shape the future of this technology and be instrumental in advancing its use in the years ahead.

So join us in exploring the possibilities and helping move this incredible technology forward!