What is the Lead Acid Battery? - Ultimate Guide

Lead acid batteries are one of our most commonly used batteries. With a history of 150 years of development, lead-acid batteries have played an indispensable role in transportation, communications, electric power, military, navigation, and aviation.

In this article, I will give you an in-depth understanding of the structure, advantages and disadvantages of lead-acid batteries, and summarize the methods for using lead-acid batteries correctly to extend battery life.

Trust me, this ultimate guide will help you get the most out of your lead-acid battery!

Lead Acid Battery Overview

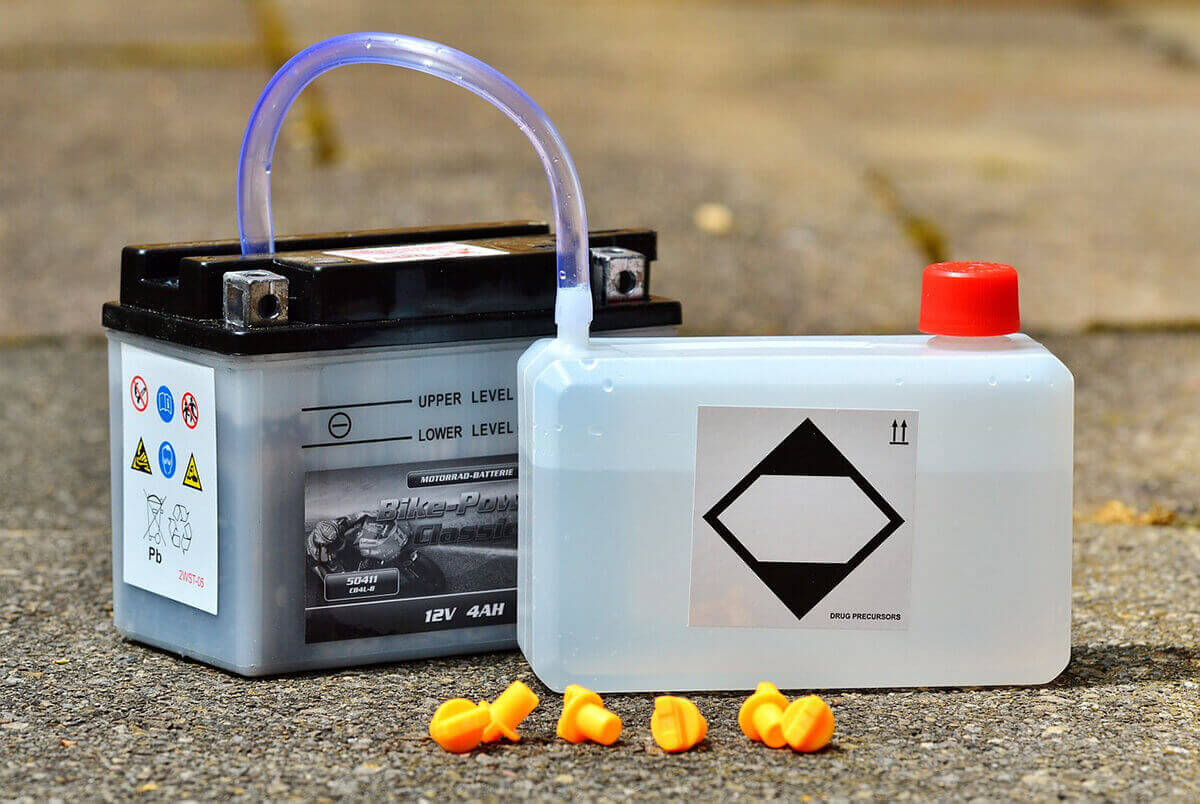

Lead-acid battery (VRLA) is a battery whose electrodes are mainly made of lead and its oxides, and the electrolyte is a sulfuric acid solution.

In the discharge state of lead-acid batteries, the main component of the positive electrode is lead dioxide, and the main component of the negative electrode is lead. In the charged state, the main components of the positive and negative electrodes are lead sulfate.

The nominal voltage of a single-cell lead-acid battery is 2.0V, which can be discharged to 1.5V and charged to 2.4V. In applications, six single-cell lead-acid batteries are often connected in series to form a nominal 12V lead-acid battery, There are 24V, 36V, 48V and so on.

Working principle

The positive electrode (PbO2) and a negative electrode (Pb) in the lead-acid battery are immersed in the electrolyte (dilute sulfuric acid), and 2V of power will be generated between the two electrodes.

Charging reaction: PbSO4 + 2H2O + PbSO4=PbO2 + 2H2SO4 + Pb

Discharge reaction: PbO2 + 2H2SO4 + Pb = PbSO4 + 2H2O + PbSO4

Composition structure

| Parts | Material | Functions |

| Positive electrode | The positive electrode is a lead-antimony-calcium alloy fence, which contains lead oxide as the active material |

|

| Negative electrode | Negative electrode lead-antimony-calcium alloy fence, containing sponge-like fiber active material |

|

| Partition | The advanced microporous AGM separator keeps the electrolyte and prevents short circuit between positive and negative electrodes. |

|

| Electrolyte | In the electrochemical reaction of the battery, sulfuric acid acts as the electrolyte to conduct ions. |

|

| Housing and Cover | Unless otherwise specified, the shell and cover are made of ABS resin |

|

| Safety valve | Made of high-quality acid- and aging-resistant synthetic rubber. |

|

| Terminal | Depending on the battery, the positive and negative terminals can be tabs, rods, studs or lead wires. |

|

Advantages of lead-acid Batteries

(1) Performance comparative advantage

At present, large-scale industrialized secondary batteries mainly include lead-acid batteries, nickel-cadmium batteries, nickel-hydrogen batteries and lithium-ion batteries. Nickel-cadmium batteries contain cadmium, a highly toxic element, and have been gradually replaced by other batteries.

Currently, the most widely used batteries on the market are lead-acid batteries, lithium-ion batteries and nickel-hydrogen batteries.

Compared with other secondary batteries, lead-acid batteries have the following comparative advantages in performance: Compared with other secondary batteries, lead-acid batteries have the following comparative advantages in performance:

- The battery with the longest industrialized production time and the most mature technology has stable performance, reliability and good applicability.

- Dilute sulfuric acid is used as the electrolyte, which is non-flammable. The battery is designed with normal pressure or low pressure, which is safe.

- The working voltage is high and the working temperature range is wide, which is suitable for high-rate discharge applications such as hybrid electric vehicles (HEV).

- It can be used for floating charging and has excellent shallow charging and shallow discharging performance. It is suitable for uninterruptible power supply (UPS), new energy storage, power grid peak shaving and valley filling and other fields.

- Large-capacity battery technology is mature and can be made into thousands of ampere-hour batteries, which provides convenience for large-scale energy storage.

(2) Cost comparative advantage

Lead-acid batteries are the cheapest secondary batteries, and the price per unit of energy is about 1/3 of lithium-ion batteries or nickel-hydrogen batteries.

In addition, the main components of lead-acid batteries are lead and lead compounds. The lead content is as high as 60% of the total battery mass. The residual value of used batteries is high, and the recycling price exceeds 30% of new batteries.

Therefore, the comprehensive cost of lead-acid batteries is lower.

(3) Comparative advantage of recycling

Lead-acid batteries have simple composition, mature regeneration technology, and high recycling value. They are the easiest batteries to realize recycling and recycling.

The global output of recycled lead has surpassed that of primary lead, the recycling rate of waste lead-acid battery lead in the United States has exceeded 98.5%, and the recycling rate of waste lead-acid battery in my country has also reached more than 90%.

Nickel-cadmium batteries and nickel-hydrogen batteries are mostly small batteries with complex compositions, high regeneration costs, and difficult recycling. It is difficult for the recycling industry to achieve market-oriented operations. The global average recycling rate is less than 20%.

Disadvantages of lead-acid batteries

(1) Low energy density

The mass and volume energy density of traditional lead-acid batteries are low, the energy density is only about 1/3 of lithium-ion batteries, about 1/2 of that of nickel-hydrogen batteries, and the volume is relatively large, so it is not suitable for lightweight and small-volume occasions use.

(2) Short cycle life

The cycle life of traditional lead-acid batteries is short, and the theoretical cycle number is about 1/3 of that of lithium-ion batteries.

There is still a lot of room for improving the cycle life of lead-acid batteries, especially lead-acid batteries with new materials, new structures and new technologies, such as bipolar lead-acid batteries and lead-carbon batteries.

(3) There is a risk of lead pollution in the industrial chain

Lead is the main raw material of lead-acid batteries. Lead accounts for more than 60% of the battery mass. Global lead-acid batteries use more than 80% of the total lead.

Lead is a heavy metal, and there is a high risk of lead pollution in the lead-acid battery manufacturing industry chain. Poor management will cause environmental pollution and harm human health.

Several Methods of Charging Lead Acid Batteries

(1) Constant current charging method

The charging current remains constant during the charging process, which is called constant current charging method, referred to as constant current charging method or equal current charging method.

During the charging process, as the battery voltage gradually increases, the charging current gradually decreases. In order to keep the charging current from decreasing due to the rising battery terminal voltage, the charging process must gradually increase the power supply voltage to maintain the charging current. The automation degree of the charging equipment is relatively high, and the simple and simple charging equipment cannot meet the requirements of constant current charging.

Constant current charging method, in the case of the maximum allowable charging current of the battery, the greater the charging current, the shorter the charging time.

In terms of time, it is advantageous to use this method. However, if the charging current remains unchanged at the later stage of charging, at this time, since most of the current is used for electrolyzing water, the electrolyte solution will appear to be boiling due to too many bubbles, which not only consumes electric energy, but also easily causes a large amount of active substances on the plate to fall off, resulting in high temperature. The rise is too high, causing the plate to bend, the capacity drops rapidly and it is scrapped ahead of time.

Therefore, this charging method is rarely used.

(2) Constant voltage charging method

In the charging process, the charging voltage remains constant all the time, which is called constant voltage charging method, abbreviated as constant voltage charging method or equal pressure charging method.

Since the constant voltage charging starts at the later stage, the power supply voltage is always kept constant, so the charging current is quite large at the beginning of charging, which greatly exceeds the normal charging current value.

However, as charging progresses, the terminal voltage of the lead-acid battery increases gradually, and the charging current decreases gradually. When the terminal voltage of the lead-acid battery is equal to the charging voltage, the charging current is reduced to a minimum or even zero.

It can be seen that the advantage of using the constant voltage charging method is that it can avoid the loss of the active material of the plate and the loss of electric energy caused by the excessive charging current in the later stage of charging.

But its disadvantage is that when charging is just started, the charging current is too large, and the volume change and shrinkage of the electrode active material are too fast, which affects the mechanical strength of the active material and causes it to fall off.

And in the later stage of charging, the charging current is too small, so the active material in the deep part of the plate cannot get the charging reaction, resulting in long-term insufficient charging, which affects the service life of the battery.

Therefore, this charging method is generally only suitable for special occasions where there is no power distribution equipment or the charging equipment is relatively simple, such as lead-acid batteries on automobiles, and small dry cell-type lead-acid batteries.

When using the equal pressure charging method to charge the lead-acid battery, the required power supply voltage: each acidic single battery is about 2.4-2.8V, and each alkaline single battery is about 1.6-2.0V.

(3) Constant voltage charging with fixed resistance

A method adopted to remedy the disadvantages of constant voltage charging.

That is, a resistor is connected in series between the charging power source and the battery, so that the current at the initial stage of charging can be adjusted.

But sometimes the maximum charging current is limited, so as the charging process progresses, the battery voltage gradually rises, but the current decays almost linearly.

Sometimes two resistor values are used, switching from low to high at about 2.4V to reduce outgassing.

(4) Stage equal current charging method

Combining the characteristics of constant current and constant voltage charging methods.

Lead-acid batteries use a larger current in the initial stage of charging, then use a smaller current after a period of time, and switch to a smaller current in the later stage of charging, that is, the method of constant current charging with different currents in different stages is called stage constant charging. flow charging method.

The charging time required by the stage equal current charging method is short, and the charging effect is also good. Since charging with a smaller current is used in the later stage of charging, the erosion of the active material on the plate by the air bubbles is reduced, and the shedding of the active material is reduced.

This charging method can prolong the service life of the battery, save electric energy, and charge thoroughly, so it is a commonly used charging method at present.

Generally, the first stage of the battery is charged with a 10h rate current, and the second stage is charged with a 20h rate current. The length of charging time at each stage, the specific requirements and standards of various batteries are different.

(5) Float charging method

Lead-acid batteries used intermittently, or only during AC power outages, are charged by float charge.

Fixed lead-acid batteries used in some special occasions are generally charged by floating charging.

The main advantage of the float charging method is that it can reduce the gassing rate of the battery and prevent overcharging.

At the same time, since the battery is connected in parallel with the DC power supply, the lead-acid battery outputs a large current instantaneously when the electrical equipment uses a large current, which helps to stabilize the voltage of the power supply system, and the electrical equipment uses electricity normally.

The disadvantage of the float charging method is that individual lead-acid batteries are unbalanced and undercharged, so regular equalization charging is required.

Factors Affecting the Life of Lead-acid Batteries

1. Depth of discharge

The depth of discharge is the extent to which the discharge starts to stop during use. The focus of design considerations is deep cycle use, shallow cycle use, or floating charge use.

If a shallow-cycle battery is used for deep-cycle use, the lead-acid battery will fail quickly. And the deeper the discharge depth, the shorter its cycle life.

2. Degree of overcharge

A large amount of gas is released during overcharging. At this time, the active material of the positive plate is impacted by the gas, and this impact will promote the shedding of the active material.

In addition, the positive grid alloy is also subject to severe anodic oxidation and corrosion, so the service life will be shortened when the battery is overcharged.

3. The influence of temperature

Lead-acid battery life increases with temperature.

Between 10°C and 35°C, every increase of 1°C will increase about 5-6 cycles; between 35°C and 45°C, every increase of 1°C can prolong the life of more than 25 cycles; The life of the negative electrode is reduced due to the loss of vulcanization capacity.

Battery life increases with temperature within a certain temperature range because capacity increases with temperature.

If the discharge capacity remains the same, the discharge depth decreases when the temperature rises, and the solid life is prolonged.

4. The influence of sulfuric acid concentration

The increase of acid density is beneficial to the positive plate capacity.

But it also increases the self-discharge of the battery, and the corrosion of the grid, which promotes the loosening and falling off of lead dioxide.

Therefore, as the density of the acid used in lead-acid batteries increases, the cycle life decreases.

5. Influence of discharge current density

As the discharge current density increases, the lifetime of the battery decreases.

Because under the conditions of high current density and high acid concentration, the positive electrode lead dioxide is loosened and falls off.

Maintenance Tips for Lead-acid Batteries

Timely charging

Lead-acid batteries have no memory, and the rapid reduction in capacity is mainly due to some reasons such as lead-acid battery vulcanization, "water loss", and "power loss".

The capacity of the battery is reduced, and the electrode plate is strained by the strong current (starting current) during discharge, and the electrode plate strain is physical damage to the battery, which cannot be repaired.

Therefore, it is inevitable to ensure that the lead-acid battery has sufficient voltage at any time.

Replenish distilled water regularly

Users generally think that maintenance-free lead-acid batteries do not need to add water, but this statement is wrong.

Lead-acid batteries will generate heat during charging and high-current discharging, and water will evaporate when there is heat.

Although the process of water evaporation is very slow, the cumulative amount of water evaporated over time cannot be underestimated.

Therefore, the lead-acid battery should be replenished with water every 6 months or so, so that the service life of the battery will be extended.

Regular deep cycle

Lead-acid batteries will inevitably have some active substances sink after being used for a period of time. If these active substances are not activated in time, it will have some impact on the capacity of the battery.

Therefore, when using electric vehicles frequently, it is necessary to deeply discharge the lead-acid battery once a quarter.

Good charger

For new lead-acid batteries, the charging process usually takes 6-8 hours, and the charger will light up green when fully charged.

If the charging time is too long, check whether the charger voltage protection device is damaged, and replace the charger in time, otherwise, the battery will be easily damaged.

In addition, do not buy a fast charger for the charger, as fast charging will also damage the lead-acid battery plates.

Prevent excessive sunlight

Excessive sunlight will increase the temperature of the battery and greatly shorten the battery life.

Inspection and cleaning

If the lead-acid battery is not cleaned in time, it will easily affect the service life and electrification effect of the battery.

The oxidation reaction is easy to occur between the pole and the chuck of this lead-acid battery, and even corrodes the metal parts at the chuck.

Therefore, pay attention to checking whether the pole and the chuck are connected tightly, whether there is corrosion and burning, whether the vent hole is blocked, whether the electrolyte is reduced, etc., and deal with it in time.

Application of Lead-acid Battery

Backup power

- Telecommunications.

- Solar system.

- Electronic switch system.

- Communication equipment: base station, PBX, CATV, WLL, ONU, STB, cordless phone, etc.

- Backup power supply: UPS, ECR, computer backup system, Sequence, ETC, etc.

- Emergency equipment: emergency lights, fire and burglary alarms, fire gates

Main power

- Communication equipment: transceiver.

- Electric control locomotives: collection vehicles, automatic transport vehicles, electric wheelchairs, cleaning robots, electric vehicles, etc.

- Machine Tool Starters: Lawnmowers, hedge trimmers, cordless drills, power drivers, power sleds, etc.

- Industrial Equipment/Instrument.

- Camera: flash, VTR/VCR, film light, etc.

Summarize

Compared with other batteries, the biggest advantage of lead-acid batteries is the mature technology, so the cost is also low, and they occupy an important position in various fields. But as our current demand for electricity is increasing, it is no longer possible to rely solely on lead-acid batteries.

Today, lifepo4 batteries have broken through the siege. With better performance, life, safety, and environmental protection, they are far superior to lead-acid batteries. They are the only batteries that can replace lead-acid batteries in the past 150 years and become the industry leader and are widely used.

So what are the differences between lifepo4 batteries and lead-acid batteries? Read the article ”Lifepo4 Battery VS Lead-acid Battery” to learn more.

Choose the Best Battery for your Solar System

Harveypower lifepo4 battery manufacturer is committed to creating the best solar energy storage battery and fully promoting global green environmental protection and energy development.

We have rack-mounted batteries and stacked batteries that can be used for household/industrial and commercial, 1-30kWh free expansion, and the king of family space saving - Powerwall.

68 core technical teams tailor a unique solar energy storage system for you.