Build an LED display outside the product group to visualize the overall data and status of the battery pack. You can also DIY the operation functions of the display according to your needs.

- Self-heated Function (Optional)

The BMS system can be set with a self-heating function to make the battery system suitable for lower temperatures.

When the temperature is below 0°C, through self-heating, the temperature of the battery can rise to above 10°C within a few tens of seconds, thereby activating the normal application of the battery.

Start heating temperature: ≤0℃. Stop heating temperature: ≥10℃.

- Bluetooth Function (Optional)

Can communicate with BMS in wireless mode. Users can connect the battery pack via Bluetooth, which allows visualizing all-important battery information such as voltage, current, temperature, SOC, SOH, errors, etc.

Some parameters and switch systems can also be controlled remotely, making everything easy to use and manage.

- State of Health (Optional)

It can detect and reflect the battery capacity, health, and performance status with the accumulation of battery usage time and the impact of the environment, effectively guiding how to maintain the battery.

Not only can we know whether the remaining available capacity of the battery can meet our demand for the total temporary power consumption, but also know when each single battery and battery pack needs to be replaced and repaired.

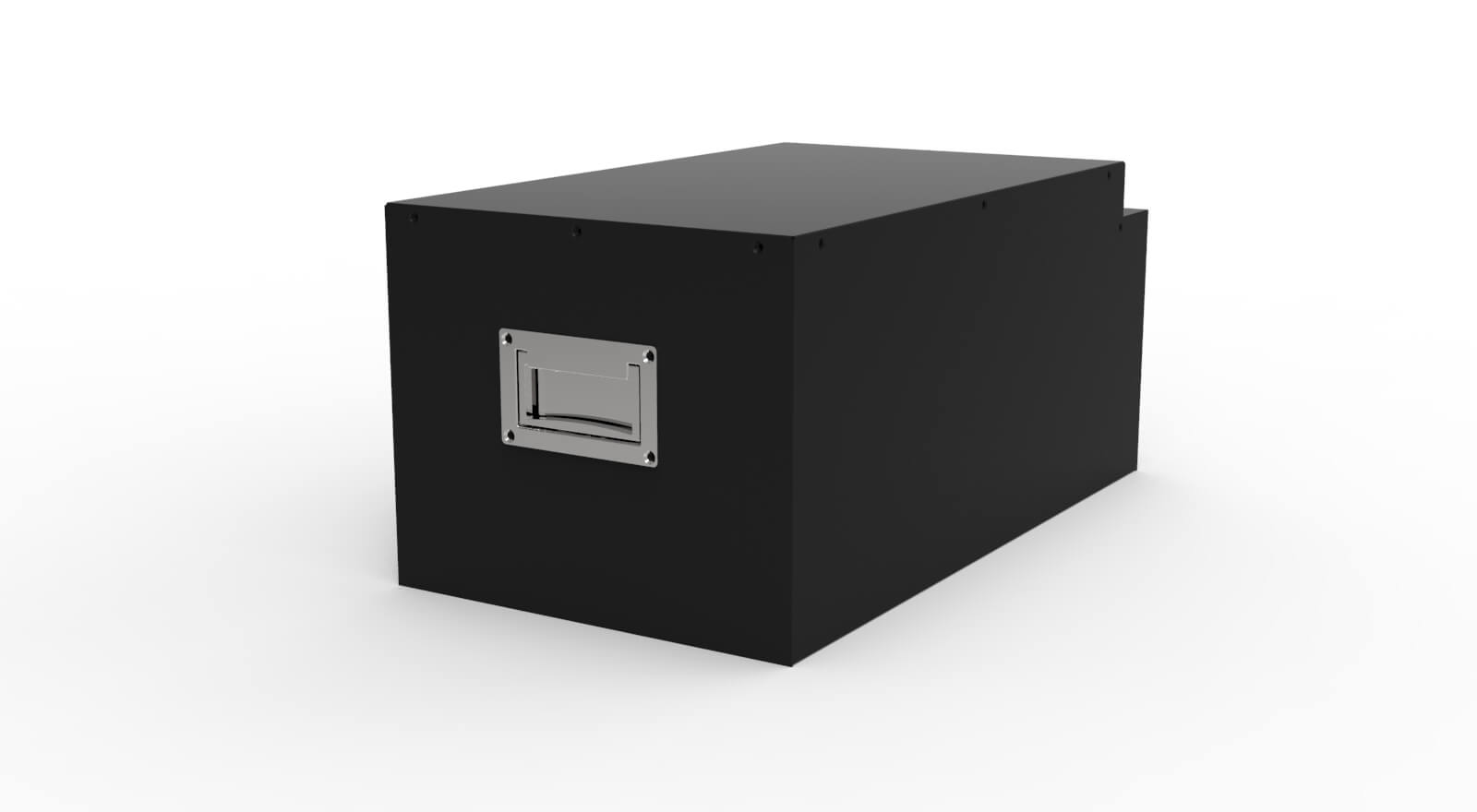

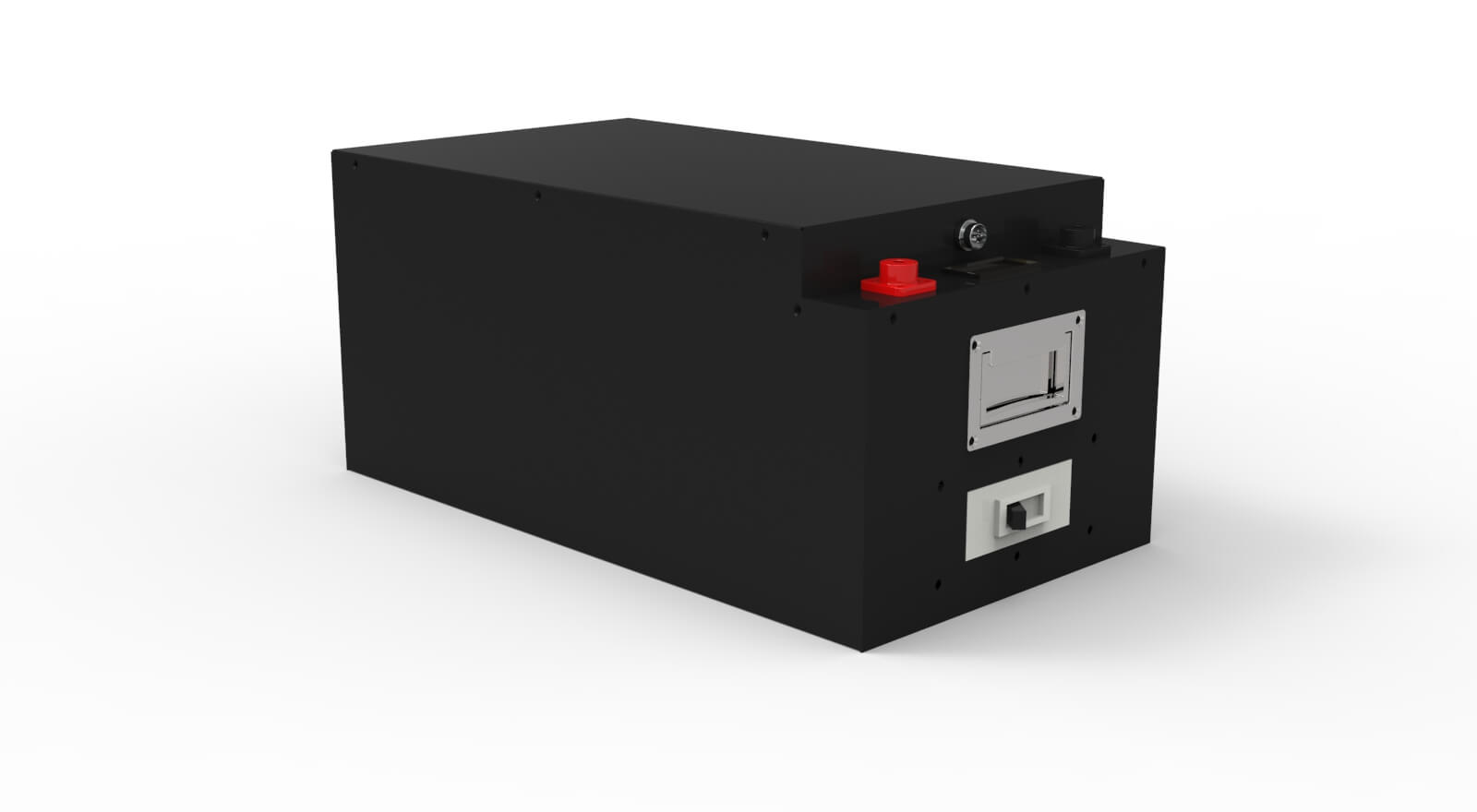

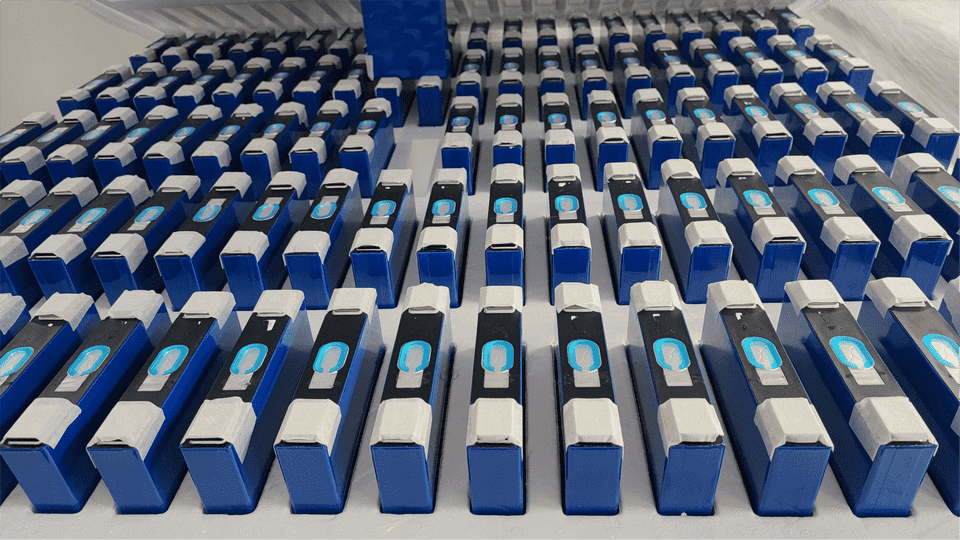

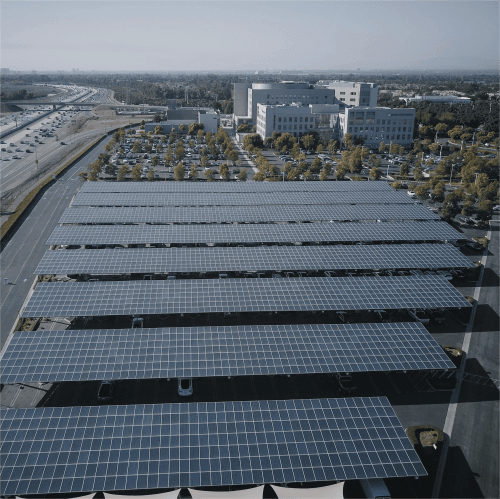

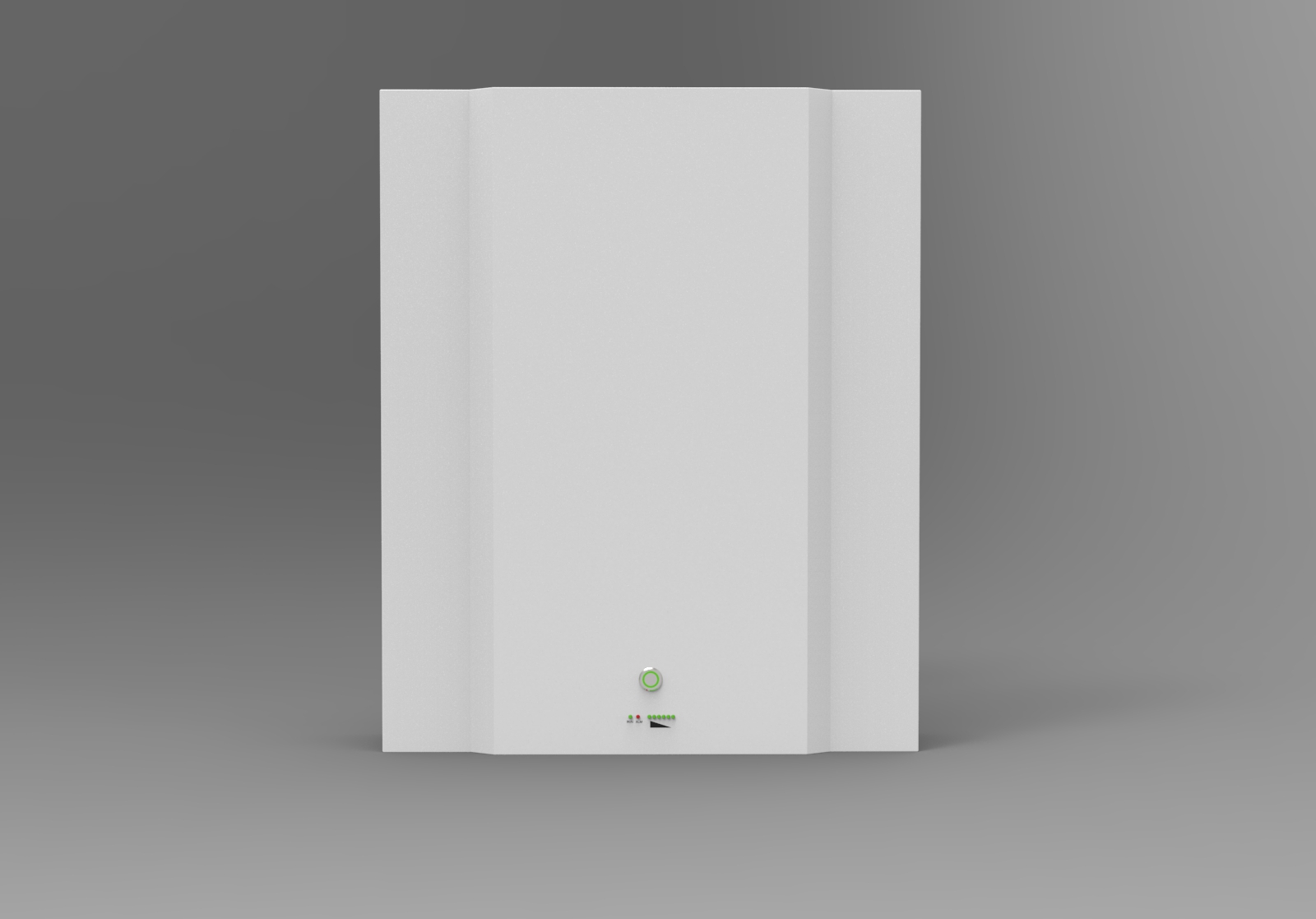

48V161Ah Powerwall Lifepo4-accu voor opslag van zonne-energie

48V161Ah Powerwall Lifepo4-accu voor opslag van zonne-energie