The Future of Negative Electrode - Silicon Lithium Battery

What is the Silicon Lithium Battery?

Lithium–silicon battery is a name used for a subclass of lithium-ion battery technology that employs a silicon-based anode and lithium ions as the charge carriers.

The biggest advantage of this type of battery is that it can provide high energy density, so it can be used to provide more power, thereby improving the performance of the car and extending the driving distance of the car.

Reasons for the Rise of Silicon Lithium Batteries

(1) The breakthrough of graphite anode reaches the bottleneck

The four key raw materials of lithium-ion batteries are positive electrode material, negative electrode material, separator and electrolyte. Anode materials have made breakthroughs earlier, and have been upgraded from early lithium cobalt oxide and lithium manganese oxide materials to lithium iron phosphate materials and ternary materials, while anode materials have been upgraded slowly, and graphite has always been the main material. In 2021, shipments of graphite anode materials will account for 98% market share of anode materials.

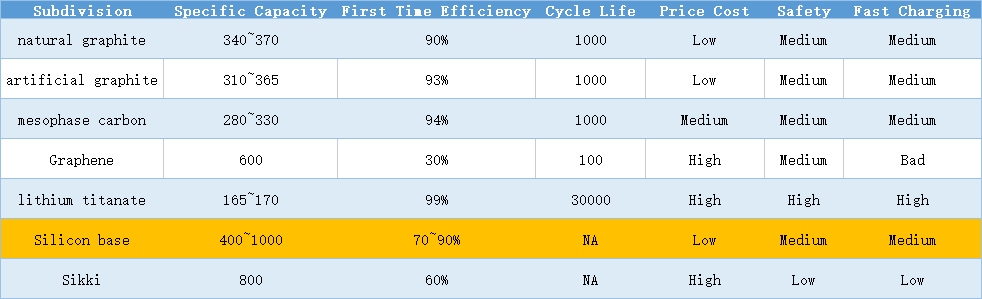

However, the current actual specific capacity of graphite anode materials is 360-365mAh/g, which is close to the theoretical specific capacity of 372 mAh/g. Improving the performance of graphite materials has little effect on improving the performance of lithium-ion batteries.

(2) The layout of leading enterprises in the application of new technologies

The 4680 battery released by Tesla, the leading automobile company, the sponge silicon battery pack released by GAC Group, the 210Wh/kg LFP battery cell released by Guoxuan Hi-Tech, and the 265kWh/kg NCM ternary battery solution provided by CATL all use silicon carbon anodes technology.

The efforts of leading lithium battery manufacturers and leading automobile manufacturers indicate that the carbon-silicon anode industry will usher in rapid development.

Anode materials are mainly divided into carbon-based and non-carbon-based, a total of more than 10 kinds. Graphite anode materials occupy more than 90% of the anode material market due to their mature technology, lower cost and better performance, and are currently the best anode material in the commercialization process. However, silicon anodes have the advantages of high energy density and wide distribution of raw materials, and are considered to be more promising anode materials for next-generation lithium-ion batteries.

The Development of Various Negative Electrode Materials:

- Have the advantages of high theoretical specific capacity (4200 mAh/g at high temperature, 2.3580 mAh/g at room temperature).

- Low delithiation potential (<0.5 V).

- Environmental friendliness.

- Abundant reserves.

- Low cost.

The Main Types of Silicon Negative Electrodes:

- Elemental silicon negative electrode, its theoretical specific capacity is as high as 4,200mAh/g, more than 10 times that of graphite negative electrode.

- The silicon oxide negative electrode has a theoretical specific capacity of 2,600mAh/g, which is also much higher than the graphite negative electrode.

Disadvantages of Silicon Lithium Batteries:

(1) Charge and discharge expansion problem

When silicon is charged and discharged, because the silicon crystal has a regular tetrahedral structure (graphite is a layered structure), it is easier to expand, and the expansion rate can reach more than 300% (the expansion rate of silicon oxide is more than 180%), resulting in the failure of the negative electrode structure. Life expectancy will be greatly reduced.

Due to the huge volume change during lithium deintercalation, the expansion of silicon negative electrode materials will cause a series of problems, including:

- The volume expansion effect will generate a large amount of shear stress and compressive stress, which will break the silicon particles, increase the internal resistance, affect the direct transmission of electrons on the electrode, and seriously cause some active materials to completely lose their electrochemical activity;

- For the entire electrode, the volume change leads to structural collapse and electrode peeling, resulting in the interruption of the electrical contact between the electrode material and the current collector, and the loss of contact between the active material and the conductive agent and binder, resulting in capacity fading.

(2) The first Coulombic efficiency is low

The first Coulombic efficiency (referred to as the first effect) is an indicator to measure the charge and discharge capacity of lithium-ion batteries. As the silicon content increases, the first effect will become lower and lower. The irreversible cycle loss of the first charge of silicon material reaches up to 30% (graphite is 5-10%).

The side reaction between the electrolyte solvent and the lithium salt will form a solid electrolyte interface (SEI) film on the negative electrode of the lithium-ion battery, and this reaction will consume lithium. The volume change makes it impossible to form a stable SEI layer on the surface of the Si electrode, and the SEI layer is repeatedly broken and formed, consuming a large amount of Li+ ions; at the same time, the thickness of the SEI increases with the electrochemical cycle, and an excessively thick SEI layer hinders electron transfer and Li+ ion diffusion. increases, the polarization increases.

Based on the current situation, it is believed that silicon is a strong contender for the next-generation anode material of lithium batteries. Replacing state-of-the-art graphite anodes with silicon could boost lithium battery storage capacity by a factor of 10. However, when charging and discharging, silicon expands and contracts, which mechanically stresses the material and leads to structural failure, eventually causing the battery to fail after only a few uses.

But a multidisciplinary research team from BeDimensional and the Graphene Flagship Program of the Italian Institute of Technology (IIT) and VARTA Micro Innovation GmbH in Austria has identified how to use graphene in practical applications as a key component to overcome the silicon expansion problem.

Silicon Lithium Batteries May Soon Become the New Industry Standard

Now, researchers at the Graphene Flagship have devised a way to make lithium batteries stable using just a small amount of graphene. This newly developed graphene-added battery can withstand 300 charge-discharge cycles, and the battery capacity is 30% higher than any existing alternative method.

The partner of the Graphene Flagship Project, Christoph Stangl from VARTA Micro Innovation GmbH, explained that only a small amount of graphene is added, enough to expand uniformly in silicon and stabilize the electrode structure, which allows people to really use the outstanding performance of silicon lithium batteries.

The graphene-added button cells have been developed to be used in countless small electronic products produced by some of the world's leading companies, including watches, wearable devices, car keys and wireless headphones. The applied industries are all fast-rising market segments.

VARTA is known for developing customized energy storage solutions, and silicon/graphene-based high-energy technological advances will lead to better batteries.

Vittorio Pellegrini of BeDimensional, a member of the Graphene Flagship, says the design milestone could be achieved with the addition of a small amount of graphene. If a large amount of graphene is added, the proportion of silicon in the battery will be reduced, and the overall capacity of the battery will be reduced. Silicon adds energy that can be stored in the battery. Due to the addition of a small amount of graphene, it is possible to prevent the failure of the battery structure while maintaining the battery capacity.

The EU-funded Graphene Flagship has helped advance this research in several ways. In the first phase of the project, not only was the initial idea of developing graphene-added batteries decided, but the company BeDimensional was established specifically to supply graphene materials and to develop many graphene-based batteries using a patented graphene production method. new technology.

The Synergistic Uses of the Graphene Flagship brings together cutting-edge research efforts from IIT companies, newly spin-off BeDimensional companies, and established industrial manufacturers like VARTA for integrated innovation. Thanks to the Graphene Flagship Pioneer projects, researchers can really focus on improving technology maturity and creating highly mature product prototypes.

Currently, the research team is working on commercializing this battery technology. The team is taking on a new challenge to develop a long-range and reliable graphene battery for electric vehicles.

The success of this collaboration demonstrates how Graphene Flagship Pioneering projects can greatly assist researchers in moving the material from the laboratory to the development of real-world components, assemblies and system integration.

Industry Mainstream Technology Route

To solve the problems of expansion and failure of silicon-negative electrode materials, a variety of silicon-negative electrode modification methods have been developed in the industry, including silicon oxidation, parameterization, compounding, colorization, alloying, and pre-lithiation. Among them, recombination, silicon oxidation, nanotechnology, and pre-lithiation technology are relatively mature and have begun to be applied in industrialization.

(1) Silicon oxide technology

The silicon oxide technology route mostly uses silicon oxide. Compared with elemental silicon particles, silicon oxide (SiOx) has a smaller volume expansion during the lithium intercalation process, so its cycle stability is significantly improved compared with pure silicon negative electrodes, but The silicon oxide negative electrode will produce inactive substances such as Li2O during the charge and discharge process, resulting in low initial efficiency of the SiOx material (about 70%).

Generally, silicon oxide is doped with a doping content of about 5%. The theoretical specific capacity of the silicon oxide negative electrode is 2600mAh/g and the cycle stability is good. Major negative electrode material manufacturers have plans for the silicon oxide negative electrode. Japan's Shin-Etsu Chemical, South Korea's Dazhou, China's Shanshan Co., Ltd., and Betray are all able to mass-produce silicon-oxygen anodes. Silicon oxide negative electrodes have been partially applied in fields such as power tools and high-end digital.

(2) Nanoization

By reducing the particle size of the silicon material to the nanometer level, the volume change of the silicon material during charging and discharging can also be improved. Nano-scale silicon materials have smaller particle sizes and more voids, which are easier to buffer the stress and deformation of silicon during the process of lithium ion extraction and extraction.

In addition, nanoparticles can shorten the diffusion distance of lithium ions and increase the lithium storage capacity of silicon materials. Although silicon nanowire anode has many advantages, its high production cost and poor material uniformity limit its large-scale application to a certain extent.

(3) Composite

The preparation of silicon composite materials by compounding other materials can not only improve the conductivity of silicon materials, but also serve as a buffer layer to withstand the volume effect of silicon during charging and discharging.

Silicon-carbon composite material (silicon-carbon anode) is the most rapidly industrialized preparation method due to its advantages of good stability, small volume change and excellent electrical conductivity. The sponge silicon anode released by GAC Group and the silicon anode patent held by SiILion, which Tesla acquired in 2021, are essentially composite structures formed by combining silicon and carbon materials.

(4) Porosity

In addition to reducing the size of silicon particles, designing porous silicon with void spaces is also an effective way to slow down the volume expansion. The void space in porous silicon can effectively reduce the volume effect caused by the intercalation and extraction of lithium in silicon particles. In addition, the void can also accelerate the wettability of the electrolyte, improve the transmission and diffusion efficiency of lithium ions in the active material, and improve the efficiency of the material. electrical conductivity.

(5) Pre-lithiation

Pre-lithiation technology is an important way to improve the initial low efficiency of silicon anodes. In order to ensure the performance of silicon anodes, it is necessary to replenish the lithium ions lost in the first cycle. Pre-lithiation technology mainly includes electrochemical pre-lithiation and adding pre-lithiation additives (lithium supplementation agents) to positive and negative electrode materials. Among them, the method of adding lithium supplementation agents is relatively mature.

Silicon Lithium Battery Market

(1) Market demand

At present, my country's silicon materials are mainly used in the consumer field (electric tools, high-end digital, etc.), and the power battery field is expected to bring exponential growth.

Since 2021, benefiting from strong demand in the consumer sector and rising demand in the international market, my country's demand for composite silicon shipments has increased from 0.6 in 2020 to 11,000 tons in 2021. GGII predicts that by 2025, the global demand for silicon anode materials is expected to grow at a compound annual growth rate of 70%.

(2) Market Penetration Rate

At present, silicon anode materials in my country are limited by cost issues, and are still mainly used in high-end batteries that are not highly sensitive to cost, and the overall permeability is low. According to the data, the penetration rate of silicon anode materials in my country has continued to grow in recent years, reaching 1.53% in 2021, and there is still a lot of room for it.