How to Test the Lifepo4 Battery Internal Resistance - Extending Life

Detecting the internal resistance of a lithium battery is an important part of maintaining and extending its life. As a professional lithium battery manufacturer, we understand the importance of obtaining accurate results quickly and efficiently. This article will give you all the information you need to understand what internal resistance is and how to test it properly.

We'll start by covering some basics, such as understanding why measuring internal resistance is so important, and explaining why taking shortcuts can lead to poor results. Next, you'll learn about the methods used by professionals and discover some tips to help improve your own testing techniques.

So if you want to take control of your battery's performance, read on! We'll make sure you're confident in your measurements every time, giving you peace of mind as you keep your lifepo4 battery healthy and running optimally.

What Is Lifepo4 Battery Internal Resistance?

What is Lifepo4 Battery Internal Resistance? Internal resistance in a lifepo4 battery refers to the electrical resistance found within its structure. This resistance impacts the performance of the cell and must be tested accurately for optimal performance from the battery.

To understand how this works, it's important to look at how a lifepo4 battery functions. The internal chemical reaction that takes place inside a lifepo4 battery creates an electric current which can then be used as energy. As electrons move through the layers of electrodes and electrolytes, they encounter various levels of obstruction due to their different resistances. These are what we refer to as 'internal resistances'. By measuring these values, engineers can determine the overall health and efficiency of their batteries.

In doing so, they can ensure proper operating conditions and maximize their power output potentials. Ultimately, accurate testing of internal resistances provides insight into a lifepo4 battery's ability to perform properly over time.

The Composition of Lithium Battery Internal Resistance

In a broad sense, like ohmic resistance (IR), activation polarization and concentration polarization can be understood as components of battery internal resistance, or as activation impedance and concentration impedance. The magnitude of activation polarization and concentration polarization needs to be calculated by establishing complex mathematical models.

The internal impedance consists of the following parts:

(1) Ion resistance

- The electrolyte inside the diaphragm

Influencing factors: Electrolyte conductivity, diaphragm area, thickness, porosity, tortuosity (Gurley)

2. The electrolyte inside the positive electrode

Influencing factors: Electrolyte conductivity, positive electrode thickness, thickness, porosity, bending coefficient.

3. The electrolyte inside the negative electrode

Influencing factors: Electrolyte conductivity, positive electrode thickness, thickness, porosity, bending coefficient.

(2) Electronic resistance

- The active material of the two electrodes

Influencing factors: Electrode conductivity, thickness, area

2. Current collector (copper foil and aluminum foil)

Influencing factors: Current collector thickness, width, length, number and position of tabs

3. Lead wires (tabs, poles, internal conductive connection elements)

Influencing factors: Dimensions, conductivity

(3) Contact resistance between the active material & the current collector

- Cathode material and aluminum foil

2. Negative material and copper foil

3. The electrochemical impedance of the battery

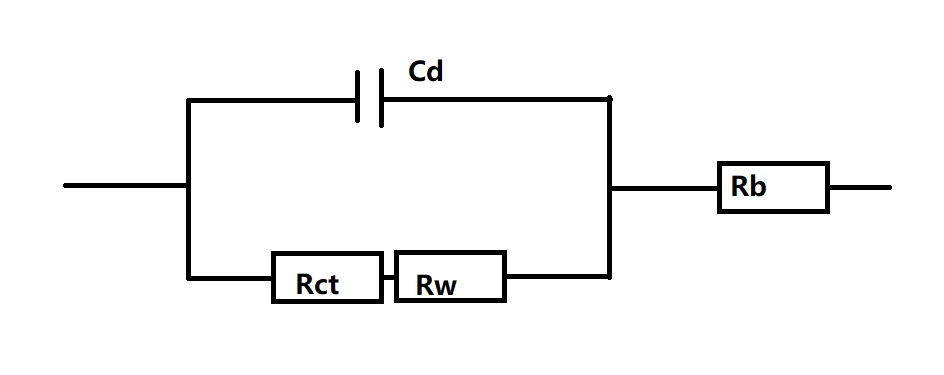

Make an equivalent circuit diagram of the electrode, which mainly consists of ohmic impedance Rb, electric double layer capacitance Cd, electrochemical reaction impedance Rct and diffusion resistance Rw.

Generally speaking, during the intercalation and extraction cycle of lithium ions, the Rb value generally changes little, while the changes of Cd and Rct are more obvious.

What Is A Good Internal Resistance For A Lifepo4 Battery?

The internal resistance of common lithium iron phosphate batteries is usually in the range of 0.6Ω-1Ω, but for batteries, the smaller the internal resistance, the better, because it is impossible to achieve zero internal resistance due to the manufacturing process and other factors. Therefore, the internal resistance of a good lifepo4 battery is usually in the range of 0.15Ω-0.3Ω.

Necessary Equipment And Tools

Testing a lifepo4 battery's internal resistance requires the right equipment. The most important tool is a multimeter, which measures electrical current and voltage in various circuits. Test leads are also necessary to connect the multimeter probes to the terminals of the battery under test. A battery charger or analyzer may be helpful as well, depending on what kind of data you want from your tests.

It's best to use specialized tools that are designed for testing batteries since these devices can provide more accurate readings than traditional meters.

Additionally, it’s important to make sure that all connections between components are secure before beginning any testing procedure. Doing so will help ensure accurate results and reduce the risk of damage to both the battery and other connected parts of the system. With this knowledge in hand, one can confidently measure their battery’s internal resistance with accuracy and ease.

Preparing The Battery For Testing

The time-honored practice of preparing a lifepo4 battery for testing is essential to ensure accurate readings. Start by gathering the materials needed, such as safety gloves and goggles, an ohmmeter or multimeter, a clean cloth, and any other cleaning products required. Then carefully remove the battery from its casing and inspect it closely for any signs of corrosion or dirt that may alter your results.

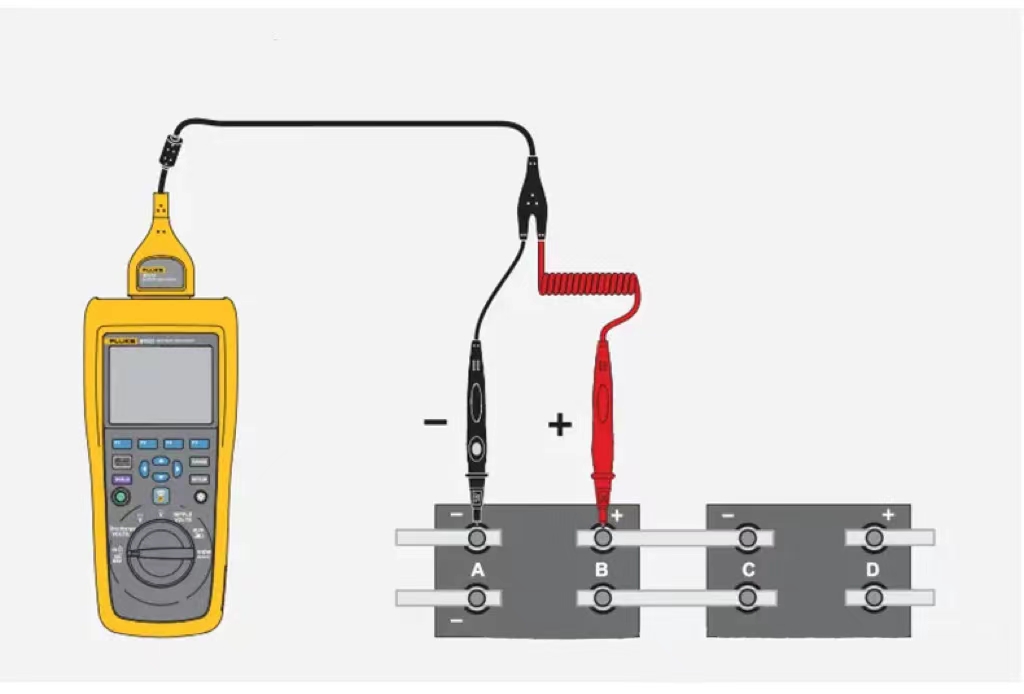

Using the cloth and cleaning product if necessary, wipe away any dust or grime from the surface of the battery so you can get clear access to its terminals. Once this has been done thoroughly, use your device's leads to connect each terminal in turn with one lead of the meter; make sure not to touch them together directly when doing this. After connecting both ends correctly, switch on your equipment and allow the current reading to settle before taking note of what it says - this will be your internal resistance measurement for that particular battery model!

Conducting The Lifepo4 Battery Internal Resistance Test

Now that preparation for testing the lifepo4 battery is complete, it's time to move on to conducting the internal resistance test. The process of measuring the battery’s internal resistance requires specialized equipment, specifically an ohmmeter or multimeter designed for this purpose. It is important to follow a specific procedure when using any type of battery testing device in order to get accurate results.

To begin, all electrical connections should be disconnected from the battery and then reconnected after setting up the test equipment. Make sure that terminals are clean and free from corrosion before connecting them to the meter leads. Once everything is connected correctly, set the meter according to manufacturer instructions. When ready, activate the power switch, which will reveal readings representing the total internal resistance of your lifepo4 cell or cells. Readings lower than normal indicate a healthy battery while higher values suggest possible damage within its components.

It is essential that these tests are conducted with caution due to potential safety risks associated with batteries containing hazardous materials such as lead acid or lithium ion cells. Additionally, make sure you use appropriate protective gear while working around batteries in case of contact with dangerous chemicals or electric shock hazards during operation. With attention paid to safety protocols along with following proper procedures for conducting a lifepo4 battery internal resistance test using specialized equipment, you can gain greater insight into your system’s performance over time and better manage how long it lasts.

Reading And Interpreting Results

Testing the internal resistance of a lifepo4 battery is a critical step in assessing its health and performance. Fortunately, with the right tools and knowledge, you can confidently analyze your test readings to understand how well your battery is performing.

Start by simply observing the numbers on your meter screen—they'll tell you what resistance value has been measured from the battery. Then use that information to gain further insight into the condition of the cell or pack. Analyzing any changes in readings over time will help you pinpoint trends and diagnose potential problems before they become catastrophic failures. Be sure to take notes as you go: tracking voltage fluctuations, temperature shifts, and other data points can give you valuable clues about underlying issues within the system.

Interpreting all this data may seem overwhelming at first—but it's really just a matter of taking things one step at a time! By breaking down each element piece by piece, understanding how they work together, and applying some basic logic when needed; anyone can quickly become an expert at reading, analyzing, and interpreting their results like a pro.

Factors That Influence Internal Resistance Test Results

Accurately testing the lifepo4 battery's internal resistance can be difficult due to a variety of factors. Temperature, age, cycle and depth discharge all influence the results of the test reading. The table below summarizes these various influences on the internal resistance test result:

| Factor | Influence |

|---|---|

| Temperature | Higher temperatures increase readings |

| Age | Older batteries show higher readings |

| Cycle | More cycles lead to increased readings |

| Depth Discharge | Deeper discharges increase readings |

The temperature has an effect because it affects how easily electrons can move between cells in a battery pack. A high temperature means that there is less resistance for current flow, resulting in higher measurements being recorded during tests.

Furthermore, as batteries age their capacity slowly decreases which also increases their measured internal resistance. Additionally, more charge/discharge cycles will create a build-up of layers on the electrodes which acts as extra insulation leading to increased resistances too.

Finally, when batteries are discharged deeply, this causes changes in chemical composition inside them resulting in raised levels of impedance and thus higher measurement values as well.

In summary, then, many elements contribute to influencing internal resistance test results, but with care and consideration, they can still yield reliable data if properly conducted. With knowledge of these variables at hand, testers should be able to make informed decisions about testing techniques and expected outcomes in order to get accurate results every time.

Alternatives To Internal Resistance Testing

When it comes to testing the lifepo4 battery, internal resistance is often thought of as the gold standard. However, there are more ways than one when it comes to testing batteries. Alternative testing methods such as battery impedance testing, electrical load testing and charge retention tests can provide valuable insight into a battery’s performance.

Cell voltage monitoring is another great way to test out a lifepo4 battery's performance in comparison to its peers. This method works by tracking how much energy is being used up or stored over time - giving you an idea of whether your battery will be able to handle the job at hand. It also allows for easy comparison between different brands or models before making any decisions on which product would best suit your needs.

At the end of the day, having knowledge about alternative tests available is key; they may not always be necessary but they are always useful tools that give us greater control over our power sources and their ability to perform consistently under duress.

Benefits Of Accurate Lifepo4 Battery Testing

Knowledge is power, and that is especially true when it comes to lifepo4 battery testing. Accurate testing of the battery’s internal resistance can be the difference between a successful operation or a malfunctioning system. Here are three key benefits to achieving accurate LiFePO4 battery tests:

- Improved Battery Performance - By getting an exact reading of the battery's internal resistance, you can fine-tune your device settings for maximum performance. This will ensure optimal energy transfer and reduce any unnecessary stress on the batteries.

- Increased Battery Life - Having precise knowledge of your battery's health gives you control over its lifespan by taking preventative measures if needed. Being able to accurately monitor the state of charge helps avoid potential damage caused by deep discharges or extended charging periods beyond what is recommended for your particular setup.

- Better System Troubleshooting - When something goes wrong with your system, being able to quickly determine which component might be causing the issue is essential in order to get back up and running as soon as possible. Knowing exactly how much current each component requires allows more targeted diagnosis and resolution of problems without having to waste time troubleshooting unrelated issues.

Overall, proper LiFePO4 battery testing provides greater insight into both existing and future systems allowing them to operate at peak performance while extending their usable life span significantly. With this increased level of knowledge, users have unprecedented control over their devices ensuring they always perform optimally no matter what situation arises.

Professional Services For Battery Testing

Accurate battery testing is essential to ensure that LiFePO4 batteries are performing optimally. Professional services for battery testing can provide peace of mind and accuracy, ensuring the safety of a system or device.

The following table provides an overview of professional services available for LiFePO4 battery testing:

| Testing Services | Benefits |

|---|---|

| Voltage Test & Capacity Measurement | Monitor energy capacity to identify any under/over-performance |

| Internal Resistance Test | Identify cell failures due to internal short circuits or other issues with distribution networks |

| Temperature Monitoring System Checkup | Ensure temperature regulation systems are working correctly to prevent thermal runaway incidents from occurring |

When selecting a service provider, it is important to find experts in lifepo4 battery testing who have experience in both commercial and residential applications. Additionally, they should be knowledgeable on the operational characteristics of different types of cells as well as certified technicians capable of running detailed tests. By investing in reliable professionals, you’ll receive accurate results and optimal protection against potential malfunctions.

In addition to technical expertise, many companies offer additional support such as remote monitoring capabilities and predictive maintenance solutions. This allows businesses and homeowners alike access to real-time data about their battery's performance which helps them make informed decisions regarding future investments and preventive measures. With these benefits combined, a properly tested LiFePO4 battery will safely power your devices while providing maximum efficiency over their lifespan.

Conclusion

In conclusion, Accurately testing the internal resistance of a LiFePo4 battery is critical for maintaining its performance and safety. Knowing how to do this properly can save you time, money, and hassle down the road. Having the right equipment and following proper procedures will help ensure accurate readings every time.

And the correct way to measure the internal resistance of the lifepo4 battery is as follows:

Set up:

- Gather all necessary materials such as a multimeter, cables, voltage source, etc.

- Connect the appropriate leads from the multimeter to the charge terminals of the battery.

- Ensure that connections are secure and firmly attached.

Testing:

- Using a high-quality digital multimeter set to measure resistance in ohms (Ω).

- Apply a constant voltage across two terminals of the LiFePo4 cell and measure the current flow through it.

- Calculate the cells’ internal resistance by dividing the applied voltage over the measured current; R = V/I.

Analysis:

- Compare results with reference values given by manufacturer or industry standards if applicable.

- Analyze the data obtained and determine whether it falls within acceptable limits or not. If yes, then great! Your LiFePo4 has ideal resistance values; however, if not then further tests may need to be done before concluding anything definitive.